Sample Projects

Additive Manufacturing Information

What's New?

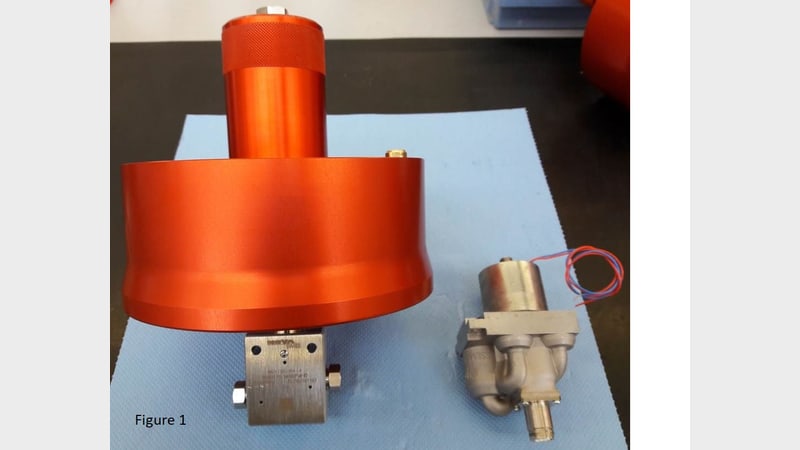

3d-prototyp GmbH, a Bossard Group company, has received the official aviation certification EN 9100:2018 in Switzerland. The seal of approval is a prerequisite for supplying…

Scientists from ETH Zurich have developed tiny 3D printed microbots that are capable of delivering drug payloads via blood vessels in the human body. More informations here.